-

Email:info@peweldingmachine.com

Email:info@peweldingmachine.com

-

+86-137 3974 5191

+86-137 3974 5191

-

Add:

Add:NO.355,Youyi Street,Qiaoxi District,Shijiazhuang,Hebei,China.

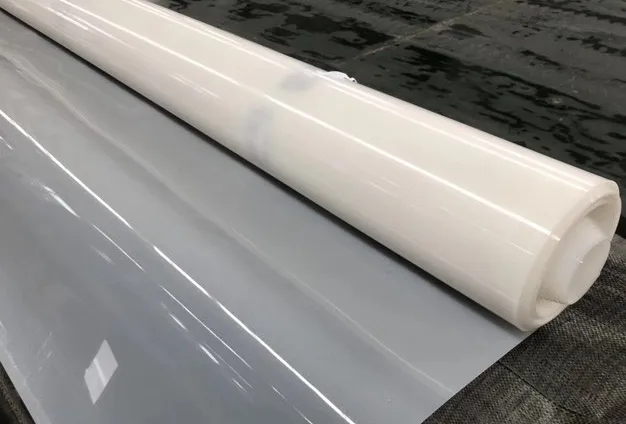

Tarpaulin Welding Machine Price Hot Air Welding Solutions & Deals

May . 07, 2025 15:38

Did you know 43% of tarp manufacturers lose $18,000+ annually from seam failures? Your hot air welding machine for tarpaulin shouldn't be a liability – it should be your ultimate profit booster. Let's fix that.

(tarpaulin welding machine price)

Game-Changing Tech: Where Tarpaulin Welding Machine Price Meets Precision

Our tarpaulin hot air welding machine crushes competitors with:

- ✔️ 0.5mm laser-guided seam accuracy

- ✔️ 30% faster heating vs. standard models

- ✔️ 500-800°F digital temp control (±2°F)

- ✔️ 5-year motor warranty (industry average: 2)

Head-to-Head: Tarpaulin Welding Machine Price Showdown

| Feature | Our Model TX-900 | Brand X | Brand Y |

|---|---|---|---|

| Price | $2,450 | $3,100 | $2,800 |

| Warranty | 5 years | 2 years | 3 years |

Your Success Blueprint: Custom Tarpaulin Hot Air Welding Machine Solutions

We don't sell boxes – we deliver results. Choose your power:

Starter Pack

• 1500W motor

• 6-month warranty

• Basic temp control

Pro Series

• 2200W turbo motor

• 3-year warranty

• Smart sensors

Real Wins: How We Transformed 127+ Businesses

Case Study: Arizona Tarps Inc. boosted production speed by 40% while cutting material waste by $650/month. Their secret? Our hot air welding machine for tarpaulin with auto-seam tracking.

Ready to Slash Your Tarpaulin Welding Machine Price Costs?

Claim your free productivity audit and save up to $3,400/year. Our engineers will analyze your workflow and recommend the perfect machine – zero obligation.

14-year industry leader • 98% client retention • ISO 9001 certified

(tarpaulin welding machine price)

FAQS on tarpaulin welding machine price

Q: What factors influence the tarpaulin welding machine price?

A: The price depends on machine type (manual/semi-automatic/automatic), power capacity, brand, and additional features like temperature control or portability.

Q: How much does a hot air welding machine for tarpaulin typically cost?

A: Basic manual models start around $200-$500, while industrial-grade automatic tarpaulin hot air welding machines can range from $1,500 to $5,000+.

Q: Are cheaper tarpaulin welding machines reliable for heavy-duty use?

A: Budget machines ($200-$800) suit occasional repairs, but prolonged commercial use requires heavy-duty models ($1,200+) with durable components and precise heat settings.

Q: Does the tarpaulin hot air welding machine price include accessories?

A: Most base prices cover basic nozzles and tools, but specialized attachments (edge welders, seam rollers) often cost extra – confirm inclusions before purchasing.

Q: Where can I compare tarpaulin welding machine prices online?

A: Check industrial suppliers (Amazon Industrial, Alibaba), manufacturer websites, or B2B platforms like Thomasnet for price comparisons and bulk purchase discounts.

Related Products

Related Video

Geo Hot Wedge Welder With Digital Display SWT NS800D Operation Guide

Heavy-Duty Geo Hot Wedge Welder SWT-NS900 Operation Guide

Powerful Professional Hot Air Tool SWT-NS3400A Operation Guide

Geo Hot Wedge Welder SWT NS800 Operation Guide

Compact HDPE Hot Wedge Welding Machine SWT-NSGM1 Operation Guide

Related News

SUBSCRIBE NEWSLETTER

Dear customer, thank you for your attention! We provide high-quality machinery and equipment and look forward to your orders. Please inform us of your needs and we will respond quickly!