-

Email:info@peweldingmachine.com

Email:info@peweldingmachine.com

-

+86-137 3974 5191

+86-137 3974 5191

-

Add:

Add:NO.355,Youyi Street,Qiaoxi District,Shijiazhuang,Hebei,China.

What Is Welding Equipment?

Our wide range of professional welding equipment can meet various welding needs. Welding inspection tools are accurate and reliable tools for measuring all aspects of welding quality, from weld strength to process compliance, providing solid data support for your welding projects and ensuring that every weld meets high standards.Geomembrane welder focuses on geomembrane welding and is suitable for various harsh construction environments. Its advanced welding technology can ensure the sealing and stability of geomembrane welding. It is widely used in large-scale projects such as water conservancy and environmental protection, providing reliable guarantees for engineering anti-seepage and protection functions.

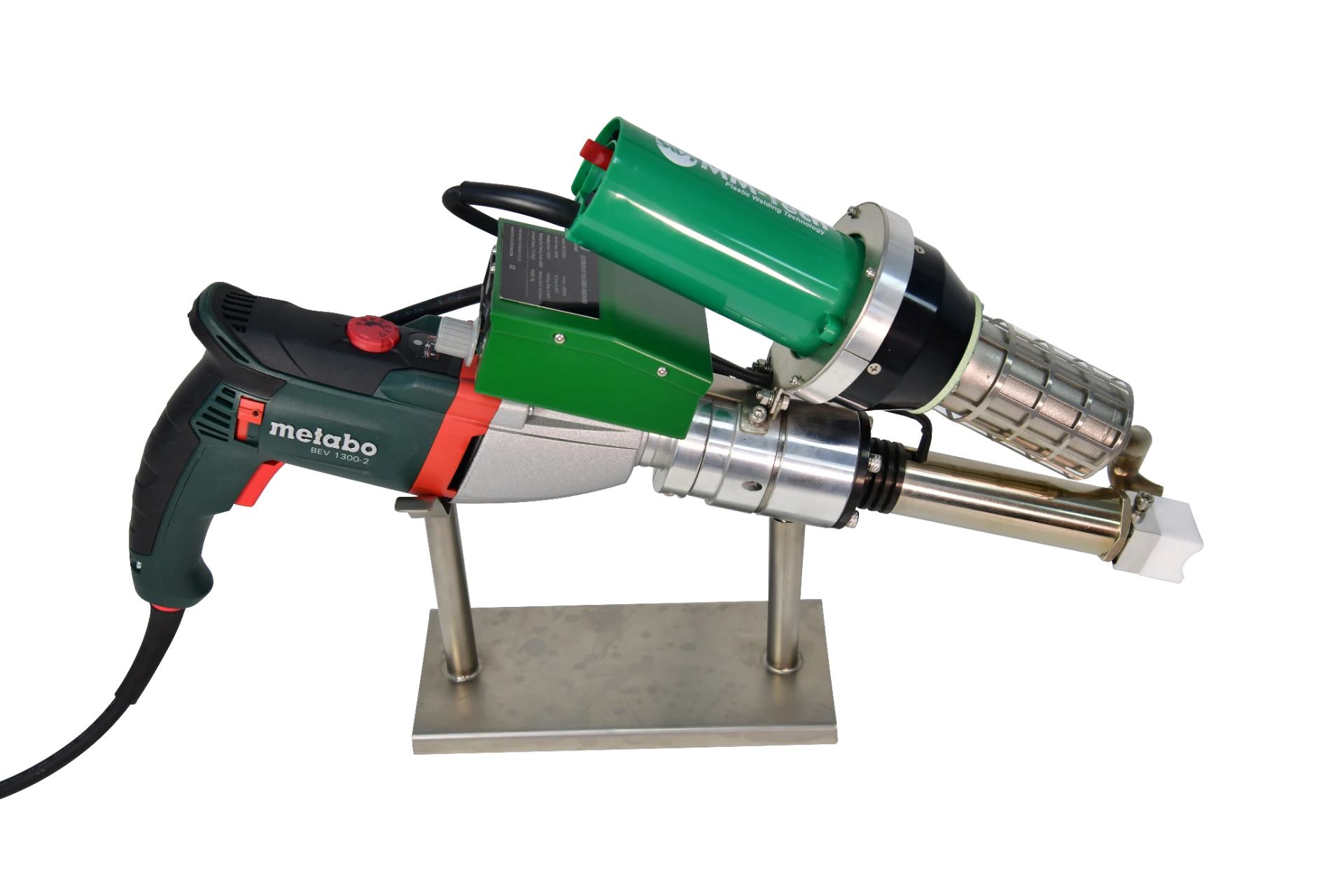

Extrusion welder, excels in the field of plastic welding. Powerful extrusion function, can be equipped with a variety of welding nozzles according to different welding needs, accurately control the extrusion amount of welding materials, suitable for welding various thick-walled plastic materials, whether it is the production of large plastic containers or the connection of industrial pipelines, it can be easily dealt with.Hot air gun, compact and flexible, is a powerful tool for fine welding and surface treatment. Adjustable temperature and wind speed settings can adapt to the welding needs of different materials, play an important role in repair, handicraft production and other fields, and provide stable hot air support for your fine work.

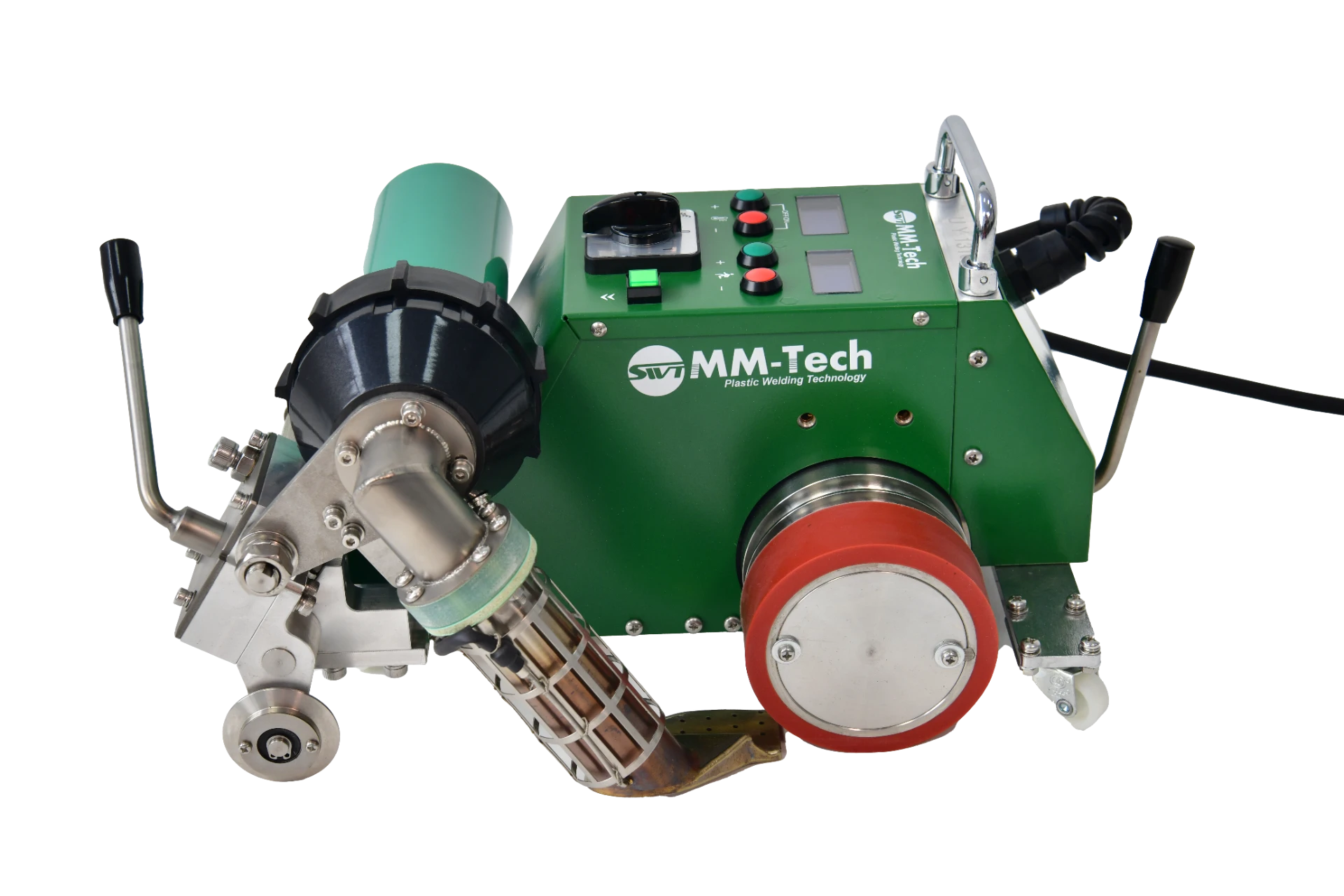

Banner Welder is designed for the advertising industry and various types of banner production. It is easy to operate and efficient. It can quickly weld banner materials together. The weld is smooth and firm, making your banner production work more efficient.Polymer welder is a welding equipment specially used for roof waterproofing projects. It mainly welds roof waterproofing materials (such as PVC, TPO and other thermoplastic films) together by hot melt welding to achieve waterproofing effects. It is widely used in roof waterproofing construction of various buildings, such as industrial plants, public venues, and residential buildings. It can effectively improve the construction quality and service life of the roof waterproofing layer.

Geomembrane Welder

Hot Air Welder

Hand Extrusion Welder

Polymer Hot Air Welder

Tarpaulin Hot Air Welder

Cx Series Welder

Poly Welding Rod

Testing Tools

Where To Use Geomembrane Welding Machines?

Where To Use A Hot Air Gun?

A hot air gun, also known as a heat gun, is a versatile tool used in various applications across different industries. It generates a concentrated flow of hot air, which can be controlled for precise heating and drying. Here’s a breakdown of its common uses:

Paint Removal: Hot air guns are widely used for stripping paint and varnish. The heat softens the paint, making it easier to scrape off without damaging the underlying surface. It’s especially effective for delicate surfaces like wood or metal.Plastic Bending and Shaping: When working with plastics, a hot air gun can be used to soften and bend materials like PVC, acrylic, or polycarbonate. This allows for custom shaping of plastic sheets or pipes without causing cracks or distortion.

Shrink Wrapping: Hot air guns are ideal for shrink-wrapping products or packaging. The heat causes the shrink film to contract tightly around the object, providing protection and a professional finish for items like electronics, gifts, or shipments.Drying and Curing: In crafts and manufacturing, hot air guns are used to speed up the drying process of paints, adhesives, and coatings. They can also be used to cure certain types of inks and resins.

Soldering and Electronics Work: In electronics, a hot air gun can be used for soldering components onto circuit boards, especially when working with surface-mount devices. The heat ensures a precise and even connection without damaging surrounding components.Defrosting and Thawing: A hot air gun can also be used to defrost pipes, locks, or other frozen surfaces, making it a handy tool in winter months.

A hot air gun is an indispensable tool for tasks involving heat-sensitive materials, offering efficiency and precision across various applications. Whether for DIY projects, professional use, or industrial purposes, this tool is designed to provide quick, effective results.