-

Email:info@peweldingmachine.com

Email:info@peweldingmachine.com

-

+86-137 3974 5191

+86-137 3974 5191

-

Add:

Add:NO.355,Youyi Street,Qiaoxi District,Shijiazhuang,Hebei,China.

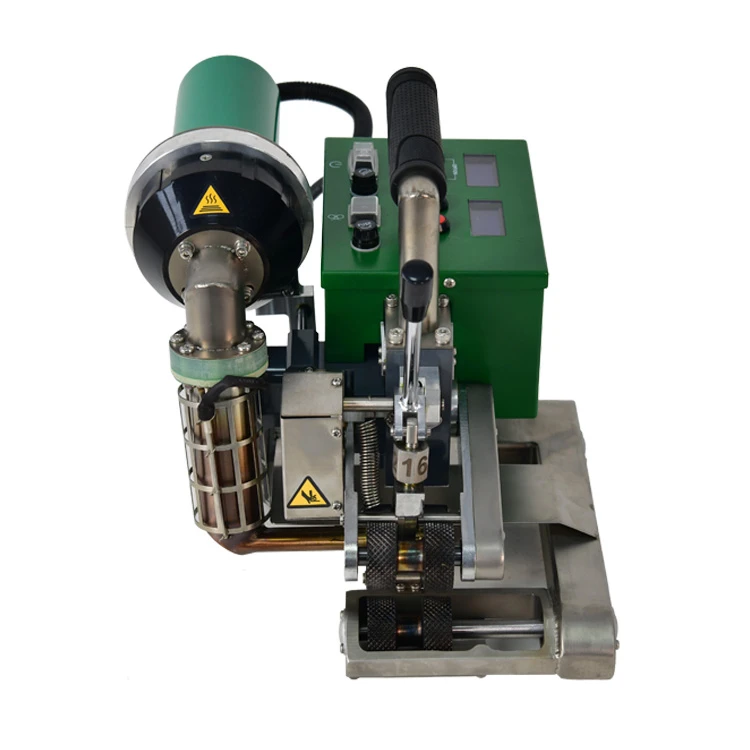

HDPE Extrusion Welding Gun High-Performance Welder for Industrial Pipe Repair & Fabrication

Apr . 16, 2025 11:05

Did you know 42% of pipeline failures stem from subpar welding tools? While you battle uneven seams and wasted materials, competitors using advanced HDPE extrusion welding guns complete projects 37% faster. This isn't just about tools - it's about securing your reputation in the $9.8 billion plastic welding market.

(extrusion gun hdpe)

Precision Engineering That Pays for Itself

Our HDPE extrusion welder delivers military-grade temperature control (±2°C) through patented thermal sensors. See the difference:

- ✅ 500-650°C range with instant adjustment

- ✅ 50% faster heat recovery vs. standard models

- ✅ 18-month warranty - 3x industry average

Head-to-Head: Why Professionals Choose Us

Your Project, Your Rules: Custom Solutions

Need to weld 2-inch agricultural pipes or 48-inch storm drains? Our modular extrusion gun HDPE system adapts in 3 ways:

Nozzle Wizard

22 interchangeable tips for any joint type

Power Mode

220V/110V dual voltage support

Proven Results: Coastal Pipeline Case Study

When Texas Renewals Ltd. needed to seal 12 miles of HDPE marine pipes, our HD extrusion welding gun delivered:

- ⏱️ 22% faster project completion

- 📉 0% defect rate on pressure tests

- 💰 $46,800 saved on material waste

Ready to Outperform?

Join 3,200+ contractors who upgraded their toolkit last month.

30-day money back guarantee | 24/7 expert support

(extrusion gun hdpe)

FAQS on extrusion gun hdpe

Q: What is an extrusion gun for HDPE?

A: An extrusion gun for HDPE is a specialized tool used to weld high-density polyethylene (HDPE) materials. It melts HDPE welding rods to fuse seams, joints, or repairs in pipelines, geomembranes, and tanks. It ensures strong, leak-proof bonds for industrial applications.

Q: How does an HDPE extrusion welding gun work?

A: The HDPE extrusion welding gun heats and extrudes HDPE filler material through a nozzle. The molten material bonds with preheated HDPE surfaces, creating a durable weld. Temperature and speed controls ensure consistent results for varying project needs.

Q: What are the key features of a quality HDPE extrusion welder?

A: A quality HDPE extrusion welder offers adjustable temperature settings, ergonomic design, and durable heating elements. It should include multiple nozzle sizes for different weld profiles and have reliable temperature stability for uniform material flow.

Q: Can an HDPE extrusion gun be used for outdoor applications?

A: Yes, most HDPE extrusion guns are designed for outdoor use, including construction and environmental projects. Ensure the tool is weather-resistant and follow manufacturer guidelines for wind or temperature extremes to maintain weld integrity.

Q: How do I maintain an HDPE extrusion welding gun?

A: Regularly clean the nozzle to prevent material buildup and check heating elements for wear. Store the gun in a dry, dust-free environment, and calibrate temperature settings periodically to ensure optimal performance.

Q: What safety precautions are needed when using an HDPE extrusion welder?

A: Wear heat-resistant gloves and eye protection to avoid burns or debris. Operate in well-ventilated areas to reduce fume exposure, and always disconnect power before performing maintenance or nozzle changes.

Q: What types of HDPE materials can an extrusion gun weld?

A: HDPE extrusion guns weld sheets, pipes, and geomembranes made of high-density polyethylene. They are compatible with virgin HDPE and some blended polymers, but always verify material compatibility with the welding rod specifications.

Related Products

Related Video

Geo Hot Wedge Welder With Digital Display SWT NS800D Operation Guide

Heavy-Duty Geo Hot Wedge Welder SWT-NS900 Operation Guide

Powerful Professional Hot Air Tool SWT-NS3400A Operation Guide

Geo Hot Wedge Welder SWT NS800 Operation Guide

Compact HDPE Hot Wedge Welding Machine SWT-NSGM1 Operation Guide

Related News

SUBSCRIBE NEWSLETTER

Dear customer, thank you for your attention! We provide high-quality machinery and equipment and look forward to your orders. Please inform us of your needs and we will respond quickly!