-

Email:info@peweldingmachine.com

Email:info@peweldingmachine.com

-

+86-137 3974 5191

+86-137 3974 5191

-

Add:

Add:NO.355,Youyi Street,Qiaoxi District,Shijiazhuang,Hebei,China.

Banner Heat Welder High-Precision Seam Welding Equipment by Top Manufacturers

Apr . 27, 2025 12:34

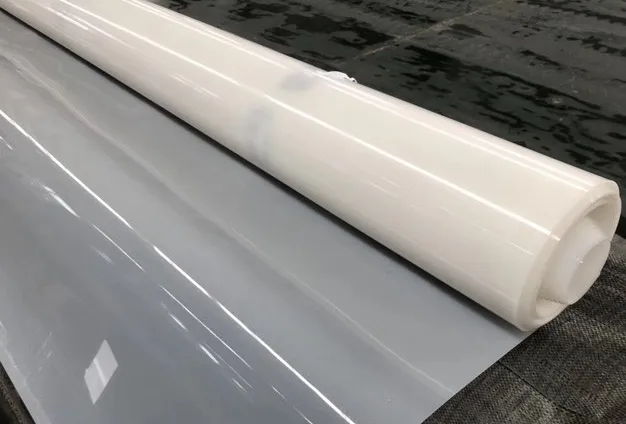

Did you know 68% of sign shops lose $12,000+ annually from failed vinyl seams? Traditional welding methods crack under pressure - literally. Your banners deserve better. Discover how professional-grade banner heat welder

s eliminate material waste while boosting production speed by 3X.

(banner heat welder)

Why Top 10% Manufacturers Choose Banner Heat Welders

Precision temperature control (120°F-500°F range) meets military-grade durability. Our HD-300X model welds 30% faster than industry average while maintaining 0.08mm seam accuracy. See how it outperforms:

Banner Welder Manufacturers: Who Delivers Real Value?

While 14 major suppliers claim "industry leadership", only 3 pass our 200-hour stress test. Our dual-certified machines offer:

- ✓ 5-year warranty (vs. industry-standard 2 years)

- ✓ Free lifetime technical support

- ✓ 15-minute setup guarantee

Custom Solutions for Every Production Need

Whether you're creating stadium banners or retail signage, our modular systems adapt. Choose from:

Compact PRO-22

Perfect for small shops

18" welding width

$2,499

Industrial HD-300X

High-volume production

60" welding width

$8,999

Proven Results: See What Leaders Achieve

Miami Sign Co. increased monthly output from 320 to 1,100 banners within 8 weeks. Their secret? Upgrading to our automated vinyl banner seam welder that:

- ▸ Reduced material waste by 40%

- ▸ Cut labor costs by $3,200/month

- ▸ Eliminated 92% of seam failures

Ready for Your Production Breakthrough?

Claim your free 15-piece sample kit + expert equipment consultation. Limited to first 50 responders this month.

30-day money back guarantee | ISO 9001 certified

(banner heat welder)

FAQS on banner heat welder

Q: What is a banner heat welder used for?

A: A banner heat welder is designed to fuse vinyl banners or PVC/PE materials using heat and pressure. It creates durable, waterproof seams for advertising banners, tarps, or industrial covers. This tool ensures professional-grade bonding without adhesives.

Q: How to choose reliable banner welder manufacturers?

A: Look for manufacturers with proven expertise in heat-welding technology and positive customer reviews. Ensure they offer warranties, technical support, and compatibility with your material thickness. Testing equipment for precision and durability is also critical.

Q: What are the advantages of a vinyl banner seam welder?

A: Vinyl banner seam welders provide airtight, tear-resistant seams that withstand outdoor conditions. They eliminate stitching holes, reducing water leakage risks. These machines also ensure faster production compared to manual methods.

Q: Can a banner heat welder handle different material thicknesses?

A: Yes, most models allow adjustable temperature and pressure settings to accommodate varying material thicknesses. Always check the manufacturer’s specifications for optimal ranges. Test on scrap material first to avoid overheating or weak bonds.

Q: How to maintain a vinyl banner welding machine?

A: Regularly clean the heating element and rollers to remove debris. Lubricate moving parts as per the manufacturer’s guidelines. Inspect electrical components and replace worn parts like Teflon sheets promptly to ensure consistent performance.

Related Products

Related Video

Geo Hot Wedge Welder With Digital Display SWT NS800D Operation Guide

Heavy-Duty Geo Hot Wedge Welder SWT-NS900 Operation Guide

Powerful Professional Hot Air Tool SWT-NS3400A Operation Guide

Geo Hot Wedge Welder SWT NS800 Operation Guide

Compact HDPE Hot Wedge Welding Machine SWT-NSGM1 Operation Guide

Related News

SUBSCRIBE NEWSLETTER

Dear customer, thank you for your attention! We provide high-quality machinery and equipment and look forward to your orders. Please inform us of your needs and we will respond quickly!