-

Email:info@peweldingmachine.com

Email:info@peweldingmachine.com

-

+86-137 3974 5191

+86-137 3974 5191

-

Add:

Add:NO.355,Youyi Street,Qiaoxi District,Shijiazhuang,Hebei,China.

Durable Welding Extruder for Sale | Best Extrusion Welder

sie . 09, 2025 06:20

In the evolving landscape of industrial fabrication, the demand for robust, reliable, and efficient joining techniques for thermoplastic materials has never been higher. At the forefront of this technological advancement is the welding extruder, a specialized tool designed to create incredibly strong and uniform welds on various plastic components. These powerful devices, often sought as an extrusion welder for sale, are indispensable in sectors ranging from civil engineering and environmental protection to chemical processing and aquaculture. This guide delves deep into the world of extrusion welding, exploring its underlying principles, technological advancements, diverse applications, and why a high-quality extrusion welder like the SWT-NS620C is a critical investment for modern industrial operations.

Current Industry Trends and the Rise of Advanced Extrusion Welding

The global market for plastic welding equipment is experiencing significant growth, driven by increasing infrastructure projects, stringent environmental regulations requiring durable containment solutions, and the expanding use of high-performance thermoplastic materials. According to recent market analysis, the thermoplastic welding market is projected to grow at a compound annual growth rate (CAGR) of over 5% from 2023 to 2030, with extrusion welding playing a pivotal role. This growth is fueled by the inherent advantages of plastics—lightweight, corrosion resistance, and cost-effectiveness—when properly joined. As industries seek more efficient and reliable methods to fabricate and repair plastic structures, the demand for sophisticated welding extruder technology, capable of producing high-integrity welds, continues to surge.

Key trends driving this demand include:

- Sustainable Infrastructure Development: Growing investments in water management (reservoirs, wastewater treatment plants), landfill lining, and mining leachate ponds heavily rely on geomembrane welding.

- Chemical and Process Industry Expansion: The need for corrosion-resistant tanks, pipelines, and scrubbers made from PE, PP, and PVC demands robust joining techniques.

- Pre-fabrication and Modular Construction: Increased off-site fabrication of large plastic structures, requiring efficient on-site welding for assembly.

- Automation and Precision: A shift towards more automated and precise welding processes to reduce labor costs and improve weld quality.

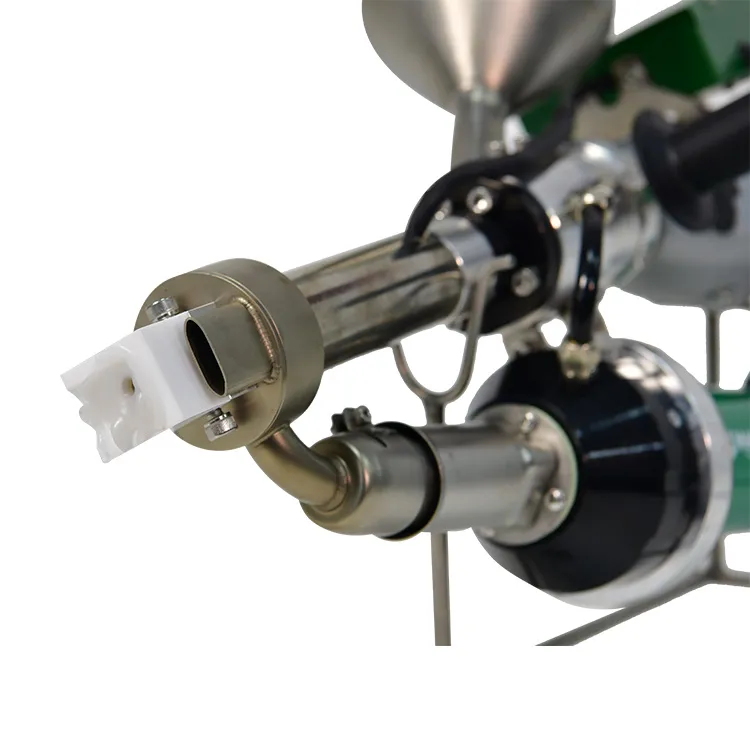

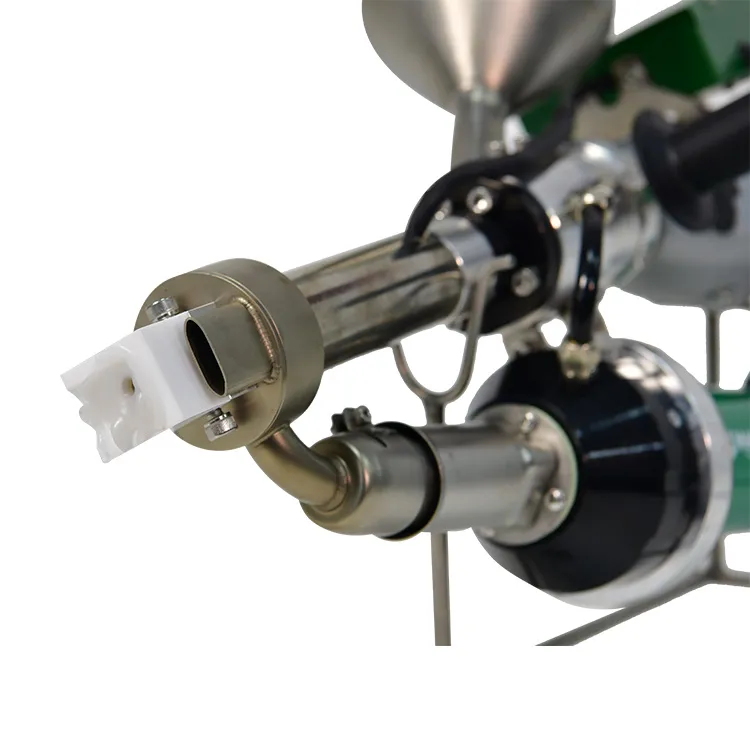

Introducing the SWT-NS620C Granules Extrusion Welding Gun: Precision and Power

At the core of advanced thermoplastic welding stands the SWT-NS620C Granules Extrusion Welding Gun, a testament to engineering excellence in the field of extrusion welder technology. Designed for heavy-duty applications, this machine offers unparalleled control, consistent performance, and robust construction, making it an ideal choice for professionals seeking an efficient extrusion welder for sale that delivers superior results.

Key Technical Parameters of SWT-NS620C

The SWT-NS620C is engineered to meet the rigorous demands of industrial welding. Its specifications are meticulously designed to ensure high output, precise temperature control, and ergonomic operation. Below is a detailed table outlining its key technical parameters:

| Parameter | SWT-NS620C Specification | Significance |

|---|---|---|

| Input Voltage | 220V (Single Phase) | Standard industrial power compatibility. |

| Heating Power (Hot Air) | 1600W | Ensures rapid and consistent pre-heating of the welding area for optimal adhesion. |

| Heating Power (Extrusion) | 1300W | Efficiently melts plastic granules or rods for smooth extrusion. |

| Motor Power | 1100W | Provides powerful and consistent extrusion force for a uniform weld bead. |

| Max Extrusion Output | 2.0-2.5 kg/h (PE/PP) | High productivity for large-scale projects, reducing project completion time. |

| Welding Rod Diameter | 3.0mm-4.0mm (Granules Supported) | Versatility in material input, accommodating both standard rods and granular feedstock for greater economy and flexibility. |

| Weight | Approx. 7.0 kg | Optimized for maneuverability and reduced operator fatigue during extended use. |

| Dimensions (L×W×H) | Approx. 520 × 120 × 380 mm | Compact design for ease of transport and use in confined spaces. |

| Welding Materials | PE (Polyethylene), PP (Polypropylene) | Broad applicability across common thermoplastic materials. |

| Temperature Control | Digital PID Controller | Precise control over both pre-heating and extrusion temperatures, crucial for weld quality and material integrity. |

| Security Features | Cold Start Protection | Prevents damage to the motor and screw by ensuring proper pre-heating before extrusion starts. |

The Manufacturing Process of a High-Performance Welding Extruder

The quality and longevity of an extrusion welder are directly tied to its manufacturing process. A robust welding extruder, like the SWT-NS620C, undergoes a meticulous production journey, ensuring each component meets stringent quality and performance criteria. This process typically involves a combination of advanced material science, precision engineering, and rigorous testing.

Detailed Process Flow: From Raw Material to Finished Extruder

Manufacturing a reliable welding extruder is a multi-stage process focusing on durability, precision, and safety. Here’s a simplified breakdown:

- Material Sourcing & Quality Control:

- Extrusion Barrel & Screw: Typically made from high-grade alloy steels (e.g., Nitrided Steel, Tool Steel) chosen for their wear resistance, corrosion resistance, and ability to withstand high temperatures and pressures. These materials often undergo specialized heat treatments (e.g., nitriding, quenching, tempering) to achieve optimal hardness and durability.

- Heating Elements: High-efficiency ceramic or mica band heaters for consistent heat distribution.

- Motor & Gearbox: High-torque, robust industrial-grade motors and precision-machined gearboxes for reliable power transmission.

- Electronic Components: Industrial-grade digital PID controllers, sensors, and wiring for precise temperature regulation and safety.

- Housing & Casing: Durable, impact-resistant engineering plastics or lightweight aluminum alloys, often manufactured through injection molding or CNC machining for ergonomic design and protection.

- Precision Machining & Fabrication:

- CNC Machining: Critical components like the extrusion screw, barrel bore, and specialized nozzles are manufactured using state-of-the-art CNC (Computer Numerical Control) machining centers. This ensures extremely tight tolerances, critical for consistent melt flow and weld bead formation.

- Casting/Forging (for heavy-duty parts): Some structural components or specialized dies might undergo casting or forging processes for enhanced strength and material integrity, followed by subsequent machining.

- Surface Treatment: Barrel interiors and screw surfaces may receive special coatings (e.g., chrome plating, bimetallic linings) to reduce friction, improve wear resistance, and prevent material sticking.

- Assembly:

- Skilled technicians assemble the various sub-systems: mechanical components (barrel, screw, gearbox), electrical wiring, heating elements, and control panels.

- Careful alignment and torque specifications are followed to ensure optimal performance and prevent premature wear.

- Calibration & Testing:

- Temperature Calibration: Hot air and extrusion heating systems are calibrated to ensure accurate temperature readings and precise control, vital for welding different thermoplastic types.

- Extrusion Output Verification: The machine's extrusion rate is tested under various load conditions to confirm it meets specified output.

- Electrical Safety Tests: Includes insulation resistance tests, ground continuity checks, and functional tests of safety interlocks (e.g., cold start protection). Adherence to ANSI/UL standards for electrical safety is often a benchmark.

- Performance Testing: Each welding extruder undergoes rigorous functional testing, including test welds on sample materials, to verify weld quality, consistency, and overall operational stability. This ensures the machine performs flawlessly under typical operating conditions.

- Final Inspection & Packaging:

- A final visual and functional inspection ensures no defects and that all accessories are included.

- Secure packaging for safe transit, often using custom-fit cases.

By adhering to these stringent manufacturing and testing protocols, leading manufacturers ensure that their extrusion welder products offer exceptional reliability, extended service life (typically 5-10 years with proper maintenance), and consistent performance in demanding industrial environments. The careful selection of materials and precision manufacturing processes contribute significantly to the overall durability and efficiency, including features like energy efficiency through optimized heating elements and robust build quality for corrosion resistance in harsh industrial settings.

Application Scenarios: Where Welding Extruders Make a Difference

The versatility and strength provided by a high-quality welding extruder make it an indispensable tool across a broad spectrum of industries. Its ability to produce thick, homogeneous welds on large plastic structures opens up numerous application possibilities where conventional hot air welding or fusion welding might fall short.

- Environmental Protection & Civil Engineering:

- Geomembrane Liners: Crucial for welding HDPE, LLDPE, and PVC geomembranes used in landfill linings, mining heap leach pads, wastewater treatment lagoons, and reservoir construction. The extrusion welder ensures leak-proof seals that can withstand environmental stresses and chemical exposure.

- Tunnel Waterproofing: Sealing waterproof membranes in tunnels and underground structures.

- Chemical & Petrochemical Industry:

- Tank Fabrication: Welding large storage tanks for chemicals, acids, and water treatment. Materials like PP and HDPE are preferred for their chemical resistance, and extrusion welding provides the necessary structural integrity for these critical vessels.

- Pipeline Systems: Joining large-diameter plastic pipes for corrosive fluid transport in industrial plants.

- Ventilation Systems & Scrubbers: Fabricating and repairing plastic ventilation ducts and air scrubbers used to manage corrosive fumes.

- Water Supply & Drainage:

- Water Treatment Facilities: Welding components of filtration systems, clarifiers, and settling tanks.

- Sewage Systems: Fabricating and repairing large-diameter sewage pipes and manholes.

- Agriculture & Aquaculture:

- Fish Ponds & Reservoirs: Sealing liners for large agricultural reservoirs, aquaculture ponds, and irrigation canals.

- Other Industrial Applications:

- Plastic Fabrication Shops: General fabrication and repair of plastic sheets, rods, and profiles.

- Automotive & Marine: Repairing plastic parts and components where strong, durable welds are required.

In all these scenarios, the extrusion welder stands out for its ability to create monolithic welds that are often stronger than the parent material, ensuring the longevity and integrity of the fabricated structure. For example, in geomembrane welding, a welding extruder can achieve bond strengths exceeding 95% of the parent material's tensile strength, a critical factor for preventing environmental contamination.

Technical Advantages of Extrusion Welding

Compared to other plastic welding methods, extrusion welding offers distinct technical advantages that contribute to its growing adoption, especially when considering the extrusion welder price against the value it delivers.

- Superior Weld Strength and Homogeneity: The extrusion process forces molten plastic through a die, creating a dense, void-free weld bead that fuses homogeneously with the base material. This results in welds that often surpass the strength of the original material, making them ideal for high-stress applications.

- Increased Welding Speed & Productivity: With high extrusion outputs (e.g., 2.0-2.5 kg/h for the SWT-NS620C), large volumes of material can be welded quickly, significantly reducing project timelines for large-scale fabrication or repairs.

- Capability for Thick Materials: Unlike hot air guns limited by material thickness, an extrusion welder can effectively weld materials ranging from 4mm to over 60mm thick, making it suitable for heavy-duty applications like tank fabrication and geomembrane lining.

- Reduced Weld Shrinkage and Distortion: The continuous flow of molten plastic and controlled cooling minimize differential shrinkage, leading to less distortion and a flatter, more aesthetically pleasing weld bead.

- Versatility in Weld Geometry: Specialized welding shoes and nozzles allow for various weld geometries (e.g., V-groove, fillet, overlap) to suit different joint configurations and application needs.

- Consistent Temperature Control: Modern welding extruders feature dual independent temperature control for both the pre-heat hot air and the molten extrudate. This precise control is crucial for optimizing the melting process for different polymers and ensuring consistent weld quality.

- Enhanced Durability and Longevity: Welds produced by extrusion are highly resistant to chemical attack, abrasion, and environmental degradation, contributing to the overall longevity and reliability of the fabricated structure. For instance, PE welds made with an extrusion welder exhibit excellent chemical resistance against a wide range of acids and bases, crucial for industrial containment.

- Reduced Operator Fatigue: While powerful, the SWT-NS620C is designed with ergonomics in mind (approx. 7.0 kg), balancing power with maneuverability, reducing operator strain during long working hours.

Manufacturer Comparison: Choosing the Right Extrusion Welder

When searching for an extrusion welder for sale, comparing manufacturers is crucial. While many options exist, key differentiators include product quality, technological innovation, customer support, and adherence to international standards. Below is a general comparison table highlighting what to consider when evaluating different welding extruder brands and how the SWT-NS620C aligns with top-tier offerings.

| Feature/Category | Standard Extrusion Welder | Premium Extrusion Welder (e.g., SWT-NS620C Class) |

|---|---|---|

| Output (kg/h) | 1.5 - 2.0 | 2.0 - 2.5+ (High productivity) |

| Temperature Control | Analog or basic digital | Dual independent digital PID control (Precise, consistent) |

| Motor Type | Brushed motor (Less durable) | Brushless/High-torque industrial motor (Longer lifespan, stable) |

| Feedstock Versatility | Rods only | Rods & Granules (Cost-effective, flexible) |

| Material Compatibility | Limited to common PE/PP | Optimized for PE, PP, some PVC, PVDF (Broader range) |

| Ergonomics/Weight | Heavier, less balanced | Optimized weight distribution (~7.0kg), ergonomic design |

| Safety Features | Basic overload protection | Cold start protection, comprehensive electrical safety |

| Build Quality | Standard components | High-grade alloys, precision CNC machined parts, robust housing |

| Warranty & Support | Limited | Extended warranty, dedicated technical support, spare parts availability |

| Certifications | May lack international certs | ISO 9001, CE, RoHS compliance (Ensures quality & safety) |

When considering the extrusion welder price, it's essential to look beyond the initial cost and evaluate the total cost of ownership, which includes durability, maintenance, energy efficiency, and the quality of the welds produced. Investing in a premium welding extruder like the SWT-NS620C often results in significant long-term savings due to reduced downtime, higher productivity, and superior weld integrity that minimizes rework and failures.

Custom Solutions and Tailored Extrusion Welding Expertise

While standard welding extruder models like the SWT-NS620C are highly versatile, certain specialized projects may require custom solutions. Leading manufacturers understand that one size does not fit all. This often involves:

- Specialized Nozzles and Welding Shoes: Custom-designed nozzles for unique joint geometries, intricate corners, or specific material thicknesses.

- Automated or Semi-Automated Systems: Integrating the extrusion welder into gantry systems or robotic arms for large-scale, repetitive welding tasks, enhancing precision and speed, especially for applications like geomembrane seaming or large pipe welding.

- Material-Specific Optimizations: Fine-tuning heating profiles, screw designs, or motor characteristics to optimize performance for less common thermoplastic materials (e.g., PVDF, ECTFE) that have specific melting and processing requirements.

- On-Site Training and Support: Providing tailored training programs for client teams to master the specific capabilities of their purchased extrusion welder and achieve optimal results on their projects.

Companies like MM-Tech Weld, with years of specialized experience in plastic welding technology, are well-positioned to offer such bespoke services, ensuring clients receive a solution perfectly matched to their unique project demands. Our commitment to innovation and customer satisfaction has established us as an authoritative source in the field of welding extruder technology since our inception.

Real-World Application Cases & Customer Successes

The impact of a reliable welding extruder is best illustrated through its successful application in various demanding environments. Our SWT-NS620C and similar extrusion welder models have been instrumental in numerous critical projects worldwide.

- Case Study 1: Landfill Liner Installation (North America): A major environmental engineering firm utilized our extrusion welders for seaming over 500,000 square meters of 2.0mm HDPE geomembrane for a new municipal solid waste landfill. The high output (2.5 kg/h) and consistent weld quality of the SWT-NS620C significantly accelerated the project timeline, reducing labor costs by an estimated 15% compared to alternative methods. Post-installation testing (e.g., air pressure testing, shear strength, and peel adhesion tests according to ASTM D6392) confirmed over 98% of welds exceeded specified strength requirements, ensuring long-term containment integrity.

- Case Study 2: Chemical Storage Tank Fabrication (Middle East): A petrochemical company required the fabrication of large polypropylene (PP) tanks for storing corrosive industrial chemicals. Using our extrusion welder, fabricators were able to create structurally sound, leak-proof tank walls up to 30mm thick. The precise temperature control allowed for optimal welding of the PP material, which is sensitive to overheating, ensuring excellent chemical resistance and an expected service life exceeding 20 years.

- Case Study 3: Water Treatment Plant Rehabilitation (Europe): For the rehabilitation of a municipal water treatment plant, aging concrete tanks were lined with new PE sheets. The compact yet powerful design of the SWT-NS620C allowed operators to work efficiently in confined spaces, achieving rapid and strong welds on complex joint geometries. This project highlighted the machine’s versatility and ergonomic benefits in challenging field conditions.

These examples underscore the critical role of a high-performance extrusion welder in delivering durable, safe, and cost-effective solutions for diverse industrial challenges. Our customers consistently report high satisfaction with the reliability and performance of our equipment, validating our commitment to quality and engineering excellence.

Frequently Asked Questions (FAQ) about Welding Extruders

Understanding the nuances of welding extruder technology is crucial for optimal performance and longevity. Here are answers to some common professional questions:

- Q1: What materials can a typical welding extruder like the SWT-NS620C weld?

- A1: The SWT-NS620C is primarily designed for welding Polyethylene (PE) and Polypropylene (PP), which are the most common thermoplastics used in industrial fabrication due to their excellent chemical resistance and durability. Some specialized extrusion welders can also handle PVC, PVDF, and ECTFE with appropriate settings and welding rods.

- Q2: What is the recommended service life of a professional extrusion welder?

- A2: With proper maintenance and regular servicing, a high-quality welding extruder like the SWT-NS620C can have an operational service life of 5 to 10 years or even longer. Key factors influencing longevity include motor care, periodic screw/barrel inspection, and replacement of wear parts like heating elements and welding shoes.

- Q3: How does cold start protection work on an extrusion welder?

- A3: Cold start protection is a critical safety and longevity feature. It prevents the extrusion welder motor from starting until the plastic material in the barrel has reached its optimal melting temperature. Attempting to extrude cold plastic can severely damage the screw and gearbox. This feature ensures the machine is always ready for safe and effective operation.

- Q4: What testing standards are relevant for welds made with an extrusion welder?

- A4: Welds made with an extrusion welder are typically tested according to international standards such as ASTM D6392 (Standard Test Method for Determining the Integrity of Nonreinforced Geomembrane Seams Produced Using Thermo-Fusion Methods), ASTM D4437 (Standard Guide for Selecting Test Methods for Geomembranes), and DVS 2207 (Welding of Thermoplastics). These standards cover tensile strength, peel adhesion, and destructive/non-destructive testing methods.

- Q5: Can I use granules instead of welding rods with the SWT-NS620C?

- A5: Yes, a significant advantage of the SWT-NS620C is its ability to utilize plastic granules as feedstock. This can be more cost-effective for large projects and offers greater flexibility in material sourcing compared to relying solely on welding rods. Ensure the granules are of suitable purity and melt flow index (MFI) for optimal results.

- Q6: What is the typical delivery period for an extrusion welder, and what warranty is provided?

- A6: For standard models like the SWT-NS620C, typical delivery periods can range from 1-3 weeks depending on stock availability and destination. Most reputable manufacturers, including MM-Tech Weld, offer a standard 12-month warranty covering manufacturing defects. Extended warranties and service contracts may also be available for long-term peace of mind.

- Q7: What kind of customer support can I expect after purchasing an extrusion welder?

- A7: A reliable supplier should offer comprehensive customer support, including technical assistance for operation and troubleshooting, access to genuine spare parts, maintenance guides, and potentially remote diagnostics or on-site service. MM-Tech Weld prides itself on offering responsive and expert support throughout the lifespan of your welding extruder.

Our Commitment: Trustworthiness and Authority in Extrusion Welding

At MM-Tech Weld, our commitment to excellence is reflected in every welding extruder we produce. With decades of accumulated experience in plastic welding technology, we understand the intricate needs of diverse industries. Our products, including the SWT-NS620C, are manufactured under stringent ISO 9001 certified quality management systems, ensuring consistent quality, reliability, and performance.

We partner with leading material suppliers and adhere to international safety standards (e.g., CE, RoHS) to guarantee not only product efficacy but also user safety. Our extensive network of satisfied clients across petrochemical, metallurgy, civil engineering, and water management sectors stands as a testament to the durability and effectiveness of our solutions. We believe that providing exceptional pre-sales consultation, comprehensive technical support, and accessible spare parts is just as crucial as delivering a high-quality extrusion welder. Our transparent delivery schedules and robust warranty policies further underscore our dedication to fostering long-term trust and partnerships with our customers.

Further Reading and Resources

For more in-depth technical information and industry insights into plastic welding and the applications of welding extruders, consider exploring the following resources:

- DVS - German Welding Society Standards (DVS 2207 - Welding of Thermoplastics)

- ASTM International - Standard Test Method for Determining the Integrity of Nonreinforced Geomembrane Seams Produced Using Thermo-Fusion Methods (ASTM D6392)

- Plastic Welding Magazine - Articles and Technical Papers (Example: Leister's knowledge hub or similar industry publication)

Pervious

Pervious

This is the first article

Related Products

Related Video

Geo Hot Wedge Welder With Digital Display SWT NS800D Operation Guide

Heavy-Duty Geo Hot Wedge Welder SWT-NS900 Operation Guide

Powerful Professional Hot Air Tool SWT-NS3400A Operation Guide

Geo Hot Wedge Welder SWT NS800 Operation Guide

Compact HDPE Hot Wedge Welding Machine SWT-NSGM1 Operation Guide

Related News

SUBSCRIBE NEWSLETTER

Dear customer, thank you for your attention! We provide high-quality machinery and equipment and look forward to your orders. Please inform us of your needs and we will respond quickly!