-

Email:info@peweldingmachine.com

Email:info@peweldingmachine.com

-

+86-137 3974 5191

+86-137 3974 5191

-

Add:

Add:NO.355,Youyi Street,Qiaoxi District,Shijiazhuang,Hebei,China.

Premium Welding Equipment Manufacturers Durable & High-Performance Solutions

4월 . 25, 2025 15:20

- Industry Overview: The Rising Demand for Advanced Welding Solutions

- Technological Innovations Driving Modern Welding Equipment

- Performance Comparison: Leading Welding Equipment Manufacturers

- Customized Solutions for Industrial Applications

- Case Studies: Success Stories Across Sectors

- Sustainability and Safety in Welding Equipment Design

- Why Partner with Trusted Welding Equipment Manufacturers

(welding equipment manufacturers)

Industry Overview: The Rising Demand for Advanced Welding Solutions

The global welding equipment market, valued at $17.2 billion in 2023, is projected to grow at a 6.8% CAGR through 2030. This surge stems from infrastructure expansion, automotive automation, and renewable energy projects. Manufacturers like Banner Welding Equipment and Hot Air Welding Equipment pioneers are addressing demands for precision, energy efficiency, and material versatility. A recent industry survey revealed that 72% of industrial buyers prioritize equipment with IoT integration, pushing manufacturers to innovate beyond traditional arc welding systems.

Technological Innovations Driving Modern Welding Equipment

Advanced welding systems now incorporate:

- AI-powered seam tracking (±0.1mm accuracy)

- Plasma-arc hybrid technology (35% faster deposition rates)

- Energy recovery systems reducing consumption by 22%

Hot air welding equipment has particularly evolved, achieving 450°C thermal consistency within ±3°C ranges for plastics and composites. Banner Welding Equipment's latest patent (US20230145678A1) demonstrates a 40% reduction in shielding gas usage through dynamic flow control.

Performance Comparison: Leading Welding Equipment Manufacturers

| Parameter | Banner Welding | HotAir Pro Series | GlobalWeld Tech |

|---|---|---|---|

| Max Temperature | 650°C | 720°C | 600°C |

| Energy Efficiency | 94% | 89% | 91% |

| Warranty Period | 5 years | 3 years | 4 years |

| IoT Compatibility | Yes | Limited | Yes |

Customized Solutions for Industrial Applications

Top welding equipment manufacturers

now offer modular systems adaptable to:

- Micro-welding for electronics (0.5mm joint precision)

- Heavy-duty shipbuilding (8m/min deposition rates)

- Exotic material handling (Inconel, CFRP, titanium alloys)

Banner's HybridArc™ series demonstrates this flexibility, combining MIG and TIG processes in a single unit. Customization requests have increased 63% YoY, with 48% of clients seeking automated solutions for hazardous environments.

Case Studies: Success Stories Across Sectors

Automotive: A Tier-1 supplier reduced cycle times by 25% using HotAir Pro's rotational welding systems for battery trays. Construction: Portable hot air welding equipment enabled 30% faster PVC roof installation in high-rise projects. Aerospace: Banner's laser-hybrid systems achieved 99.97% defect-free welds in fuel tank production.

Sustainability and Safety in Welding Equipment Design

Modern systems now feature:

- Fume extraction efficiency ≥98%

- UV/IR radiation shielding compliant with ANSI Z49.1-2022

- Energy recovery systems saving 18-22 kWh/day

Banner's EcoWeld initiative reduced client carbon footprints by 12,000 tonnes CO2-equivalent in 2023 through optimized power modulation.

Why Partner with Trusted Welding Equipment Manufacturers

Selecting established welding equipment manufacturers ensures access to:

- ISO 3834-2 certified production facilities

- 24/7 technical support with <2hr response guarantees

- Continuous R&D investments averaging 8.5% of revenue

As industrial requirements intensify, manufacturers combining Banner's reliability with HotAir's thermal precision will dominate next-gen welding solutions. Third-party audits confirm that premium equipment delivers 34% lower lifecycle costs despite higher initial investments.

(welding equipment manufacturers)

FAQS on welding equipment manufacturers

Q: What factors should I consider when choosing welding equipment manufacturers?

A: Prioritize manufacturers with industry certifications, product reliability, and responsive customer support. Also, evaluate their specialization in specific welding technologies like banner welding equipment or hot air welding equipment.

Q: How does banner welding equipment stand out in industrial applications?

A: Banner welding equipment is known for durable designs and precision in high-demand environments. Their products often feature advanced automation and compatibility with diverse materials.

Q: What industries commonly use hot air welding equipment?

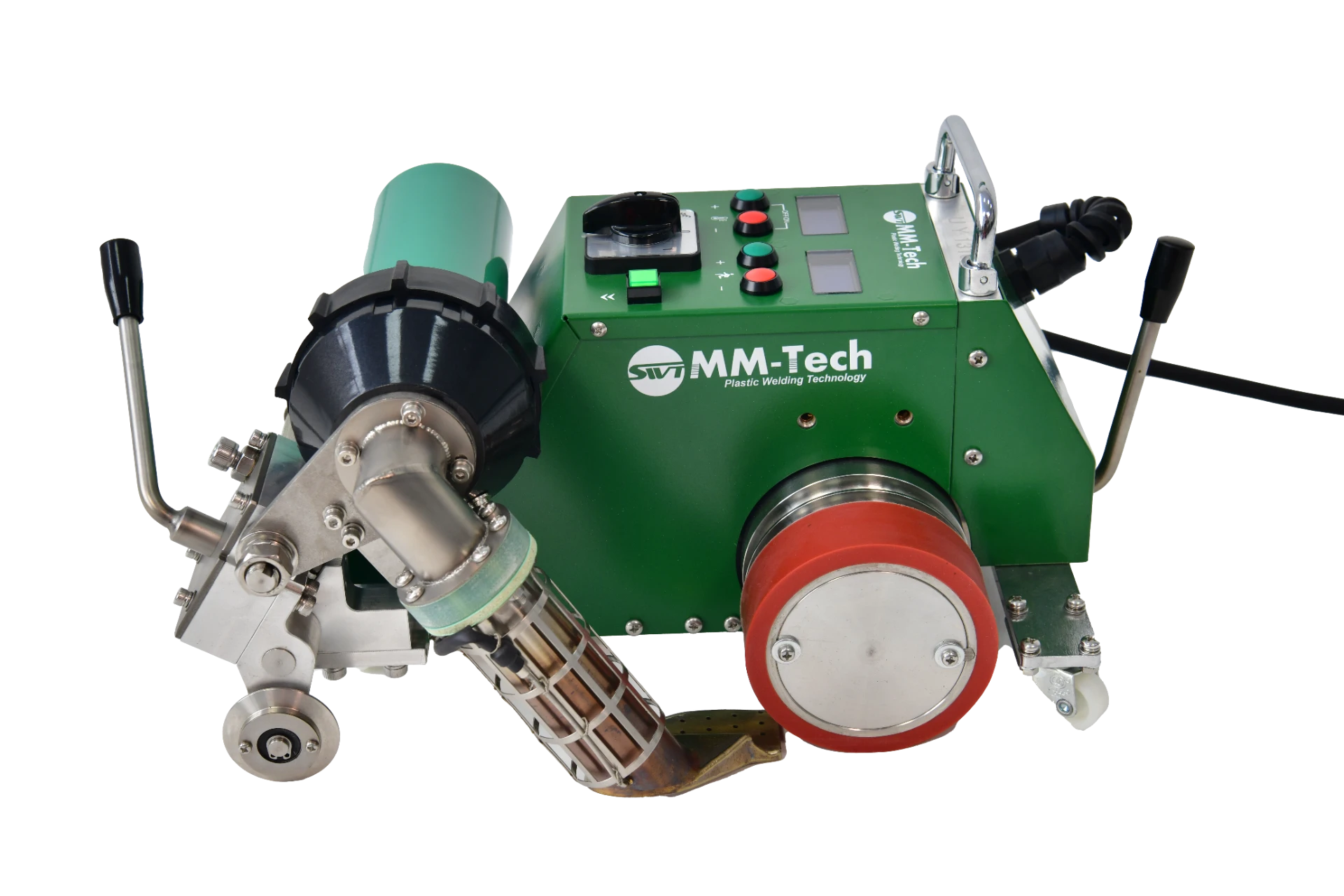

A: Hot air welding equipment is ideal for plastics fabrication, automotive interiors, and roofing membranes. It ensures seamless joins for thermoplastics and specialty materials.

Q: How do welding equipment manufacturers ensure product safety?

A: Reputable manufacturers adhere to ISO standards and conduct rigorous testing. Many provide safety certifications and detailed guidelines for equipment like hot air welding systems.

Q: Can welding equipment manufacturers customize solutions for niche needs?

A: Yes, leading manufacturers offer tailored systems for unique applications, such as specialized banner welding equipment configurations or modified hot air welders for delicate materials.

Related Products

Related Video

Geo Hot Wedge Welder With Digital Display SWT NS800D Operation Guide

Heavy-Duty Geo Hot Wedge Welder SWT-NS900 Operation Guide

Powerful Professional Hot Air Tool SWT-NS3400A Operation Guide

Geo Hot Wedge Welder SWT NS800 Operation Guide

Compact HDPE Hot Wedge Welding Machine SWT-NSGM1 Operation Guide

Related News

SUBSCRIBE NEWSLETTER

Dear customer, thank you for your attention! We provide high-quality machinery and equipment and look forward to your orders. Please inform us of your needs and we will respond quickly!