-

Email:info@peweldingmachine.com

Email:info@peweldingmachine.com

-

+86-137 3974 5191

+86-137 3974 5191

-

Add:

Add:NO.355,Youyi Street,Qiaoxi District,Shijiazhuang,Hebei,China.

High-Efficiency Plastic Extrusion Welding Machine for Precision Joints

7月 . 26, 2025 12:01

Official Website: https://www.mmtechweld.com

Contact: +86-311-80662170

Mobile: 137 3974 5191

Email: info@peweldingmachine.com

Address: NO.355, Youyi Street, Qiaoxi District, Shijiazhuang, Hebei, China

The global demand for plastic extrusion welding machine and related equipment like extrusion welding machines, plastic extrusion welders, and extruder welding machines has risen sharply due to advancements in thermoplastic processing technology and infrastructure needs across industries. From chemical containment systems to civil engineering membrane structures, the precision and reliability of plastic extrusion is now vital.

According to the PlasticsToday industry forum, growth in environmentally sustainable infrastructure, water supply, waste management and geomembrane systems are fueling the need for advanced extrusion welding technology (Plastic Welding: A Comprehensive Guide). The trend as of 2024 is towards higher output machines, improved digital controls, and multi-material compatibility. Polyethylene (PE), polypropylene (PP), and polyvinylidene fluoride (PVDF) are the most demanding thermoplastics for extrusion joining.

| Parameter | Description | Typical Range |

|---|---|---|

| Extruder Motor Power | Supplies torque & speed for plastic feed extrusion | 800W – 2000W |

| Hot Air Blower Power | Preheats weld interface with adjustable temp | 1200W – 3400W |

| Max. Extrusion Output | Plastic melt output per hour | 2.0 – 7.5 kg/h |

| Welding Rod Diameter | Feedstock for welding, shape & size | Ø3 mm – Ø5 mm |

| Applicable Materials | Thermoplastics supported | PE, PP, PVDF, etc. |

| Welding Temperature Range | Controlled via PID or digital; accuracy critical | 20°C – 360°C |

| Weight & Ergonomics | Handheld/portable or fixed systems | 4.5 kg – 9 kg |

| Digital Control | Interface for monitoring temp/speed | Analog/Digital PID, Touchscreen |

Description:

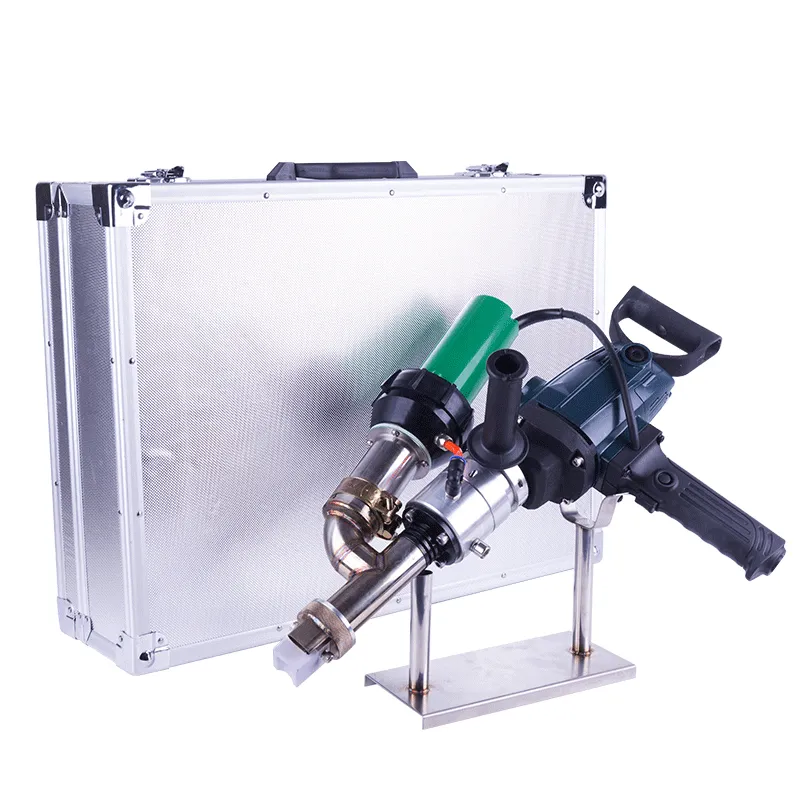

This SWT-NS600F hand extruder is suitable for welding thermoplastic materials such as PP, PE, PVDF, and other hot melt plastic materials. It has a large extrusion volume and high efficiency, making it ideal for welding and repairing most pipes and membrane structures.

Product Page: https://www.mmtechweld.com/swt-ns600f-plastic-extrusion-welding-machine.html

SWT-NS600F Main Technical Specifications

| Specification | Unit | SWT-NS600F |

|---|---|---|

| Extrusion Motor Power | W | 1300 |

| Hot Air Blower Power | W | 1600 |

| Max. Extrusion Output | kg/h | 5.5 |

| Welding Rod Diameter | mm | 3.0 - 5.0 |

| Applicable Materials | - | PE, PP, PVDF |

| Heating Mode | - | Independent dual heating |

| Temperature Range | °C | 20 ~ 360 |

| Control System | - | Digital intelligent control |

| Weight | kg | 7.5 |

| Noise | dB | < 70 |

- Tank and vessel fabrication for chemical storage

- Welding of geomembrane liners in civil engineering, landfills, and ponds

- Plastic pipe joining and repair in water, sewage, and industrial pipework

- Manufacture and repair of ducting, fume extraction systems, air conveying systems

- Thermoplastic roofing and waterproofing membrane installation

- Structural reinforcement in plastic fabrication workshops

- Any hot-melt thermoplastic joining applications demanding high weld integrity

A1: The model supports Polyethylene (PE), Polypropylene (PP), and Polyvinylidene Fluoride (PVDF)—each widely used in industry for their strength and chemical resistance.

A2: The machine can extrude up to 5.5 kg/h, making it one of the highest efficiency hand-held extruder welding machines available in the market.

A3: This extruder welding machine uses a dual digital heating system with intelligent feedback regulation, precise to single-degree increments for both extruder barrel and hot air interface.

A4: It complies with key industry standards such as DVS 2207-4 for hot-gas/extrusion welding of thermoplastics and EN 60335-1 on electrical safety.

A5: The SWT-NS600F accepts welding rods of 3.0 mm to 5.0 mm, accommodating a range of mechanical requirements and joint geometries.

A6: At 7.5 kg, it’s engineered for balanced handheld operation while delivering industrial-grade power. Its robust ergonomic design allows for extended use with minimal fatigue.

A7: Yes. The SWT-NS600F is designed with universal welding shoe options and a flexible, compact form, making it suitable for both membrane seams and pipe junctions.

HEBEI MINGMAI TECHNOLOGY CO., LTD. is a recognized expert and manufacturer in the field of plastic extrusion welding machines. Over years, the company has delivered thousands of high-tech extrusion welding machines and plastic welders to customers worldwide across municipal, industrial, water management and civil engineering sectors. With strict quality control, professional engineering, and a dedicated service team, MMTECH supports the global industry’s push towards more efficient, safer, and more sustainable plastic joining solutions.

- Comprehensive support from machine selection to on-site commissioning & training

- Industry-leading after-sales service & spare parts supply

- Contribution to technical standards; trusted by major infrastructure projects globally

- Digitalization: Integration with IoT and real-time process feedback for consistent quality

- Automation: Growth of semi-automated and robotic extrusion welding systems

- Multi-material processing: Enhanced compatibility with engineered thermoplastics

- Green Manufacturing: Focus on recycled plastics and improved energy efficiency

- Remote Diagnostics: Digital support & troubleshooting via smart interfaces

- Portability Upgrades: Lighter, more ergonomic welders without compromise on power

- Smart Safety: PID/AI-enabled overload, temp and circuit protection

As infrastructure modernization and industrial plastics manufacturing advance, state-of-the-art plastic extrusion welding machine, such as the SWT-NS600F by HEBEI MINGMAI TECHNOLOGY CO., LTD., will drive higher productivity, reliability, and sustainability for projects worldwide. By leveraging up-to-date machine designs, digital control, and flexible application, fabricators achieve secure, standardized welds across the full spectrum of thermoplastic materials. For project partners and industry professionals, MMTECH stands as a trusted manufacturer—blending experience, innovation, and service for plastic extrusion welding excellence.

[1] PlasticsToday Industry Forum: Plastic Welding: A Comprehensive Guide

[2] DVS – German Welding Society: DVS 2207-4: Welding of thermoplastics

[3] ScienceDirect – Material Joining Research: Extrusion Welding - ScienceDirect Topics

[4] Wiley Online Library: Plastics Joining and Welding Handbook

Pervious

Pervious

This is the first article

Related Products

Related Video

Geo Hot Wedge Welder With Digital Display SWT NS800D Operation Guide

Heavy-Duty Geo Hot Wedge Welder SWT-NS900 Operation Guide

Powerful Professional Hot Air Tool SWT-NS3400A Operation Guide

Geo Hot Wedge Welder SWT NS800 Operation Guide

Compact HDPE Hot Wedge Welding Machine SWT-NSGM1 Operation Guide

Related News

SUBSCRIBE NEWSLETTER

Dear customer, thank you for your attention! We provide high-quality machinery and equipment and look forward to your orders. Please inform us of your needs and we will respond quickly!