-

Email:info@peweldingmachine.com

Email:info@peweldingmachine.com

-

+86-137 3974 5191

+86-137 3974 5191

-

Add:

Add:NO.355,Youyi Street,Qiaoxi District,Shijiazhuang,Hebei,China.

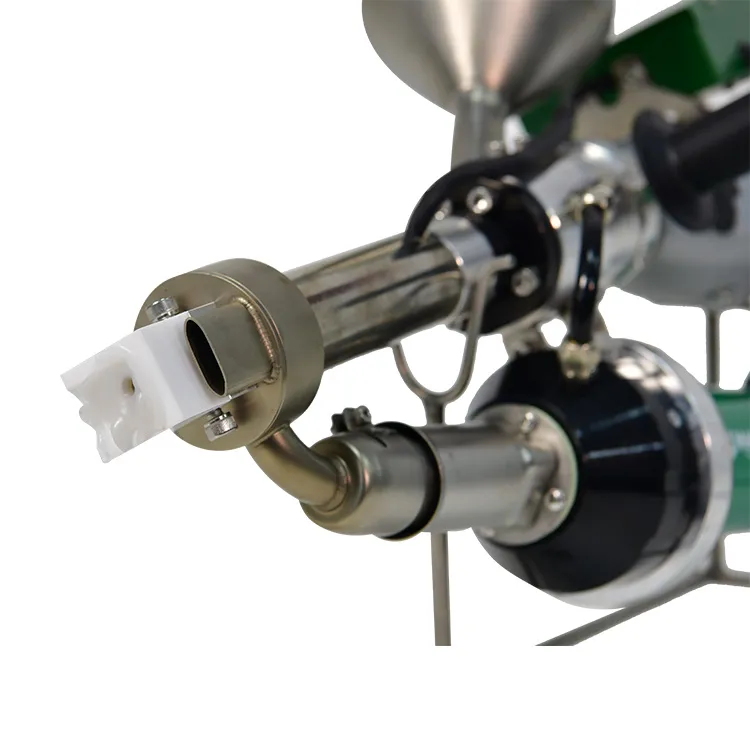

HDPE Extrusion Welding Gun for Efficient HDPE Pipe Joining & Repair

Juil . 07, 2025 12:09

Struggling with leaks and weak joints in your HDPE projects? You’re not alone. Over 48% of HDPE pipeline failures arise from poor welding, costing businesses millions every year. The good news? Innovative HDPE extrusion welding gun solutions are revolutionizing this industry, offering unmatched strength, speed, and reliability. If you want flawless welds and reduced downtime, it's time to discover why the right extrusion welding tool makes all the difference.

(hdpe extrusion welding gun)

Why Choose an HDPE Extrusion Welding Gun?

Picture this: seamless welds, zero leaks, outstanding durability. That’s what you get with a top-tier hdpe extrusion welding gun

. Unlike traditional fusion methods, these guns deliver precise control. They combine heat and pressure in one motion, ensuring melt consistency and high structural performance. Reliable statistics show that extrusion welding can boost joint efficiency by up to 25% compared to manual fusion. The advanced digital controls and self-calibrating options offered by modern guns make them user-friendly for operators at any skill level.

- Welding speeds up to 5x faster than manual fusion

- Uniform bead formation for optimal strength

- Compatible with both PE and PP pipe

- Error-proof digital temperature control

Tired of rework? Let’s put an end to costly callbacks, boost safety, and bring peace of mind to every install.

Top Manufacturer Comparison: Your Ideal Match?

Not all hdpe extrusion welding machines are created equal. We compared industry favorites—here's what you need to know.

What matters most to you? Output speed, weight, or warranty? Your ideal extrusion welding HDPE pipe solution is here—tailored to your project’s demands.

Custom HDPE Extrusion Welding Solutions for Every Project

Every job is unique. That’s why leading HDPE extrusion welding machine manufacturers offer tailored setups—no more one-size-fits-all. Need specific nozzle shapes? Variable speed controls? Extra-high output for industrial-scale jobs? All possible. You can select voltage options, handle design, and portability features. The result: a tool engineered for your workflow, minimizing fatigue and maximizing performance.

- Customizable settings for pipe diameters up to 1200mm

- Ergonomic design for long shifts

- Easy-to-service construction—minimal downtime

- Industry certifications for safety and compliance

Real-World Success: Application Case Studies

Seeing is believing. Let’s look at where hdpe extrusion welding guns have delivered game-changing results:

Municipal Water Supply Upgrade, Texas (2023):

16 miles of HDPE pipe welded in half the projected time. Weld failures: zero. City reported a 40% reduction in future maintenance budgets.

Industrial Chemical Plant, Germany (2022):

Custom hdpe extrusion welding machine used for complex manifold work. Achieved perfect seals on 50+ flanges. Production downtime cut by 60%.

Agricultural Irrigation Expansion, Australia (2023):

High-speed extrusion welding enabled the connection of massive diameter pipes, finishing two weeks ahead of schedule, boosting grower profits by $150,000.

Imagine what your team could achieve with the right tools. Would you risk your next project on outdated equipment?

Ready to Transform Your Workflow? Choose the Best HDPE Extrusion Welding Guns Today!

Don’t let weak joints undermine your reputation. Choose a hdpe extrusion welding gun that works as hard as you do. At [Your Company Name], we bring you only the most reliable, high-performance extrusion welding solutions—backed by real-world results, certified durability, and custom configuration.

- Expert pre-sales support and fast shipping worldwide

- After-sales service you can count on, 24/7

- Decades of manufacturing excellence in HDPE welding

Your next project deserves better welds, speedy installation, and zero headaches. Contact us now and experience the future of extrusion welding. Let us help you build stronger—today!

(hdpe extrusion welding gun)

FAQS on hdpe extrusion welding gun

Q: What is an HDPE extrusion welding gun?

A: An HDPE extrusion welding gun is a tool used to join HDPE materials by melting and fusing them. It delivers a heated plastic extrudate through a nozzle to bond two surfaces. This method ensures strong, durable welds for pipes and sheets.

Q: Can I weld HDPE pipes using an extrusion welding machine?

A: Yes, you can weld HDPE pipes using an extrusion welding machine. The machine softens the material and extrudes molten plastic to join pipe sections securely. This process is common in plumbing and industrial applications.

Q: What materials are suitable for hdpe extrusion welding?

A: HDPE extrusion welding guns are mainly used for welding HDPE, but can also be used with other thermoplastics like PP and PVC. Ensure material compatibility before welding. This ensures a strong and reliable bond.

Q: How do I maintain an hdpe extrusion welding machine?

A: Regularly clean the nozzle and extruder to prevent plastic buildup. Check heating elements and drive motors for proper functioning. Always follow the manufacturer's maintenance instructions.

Q: Is extrusion welding hdpe pipe better than traditional joining methods?

A: Extrusion welding offers strong, homogeneous joints that can outperform some mechanical fittings. It's particularly useful for complex shapes and repairs. However, proper technique and equipment are essential for quality results.

Related Products

Related Video

Geo Hot Wedge Welder With Digital Display SWT NS800D Operation Guide

Heavy-Duty Geo Hot Wedge Welder SWT-NS900 Operation Guide

Powerful Professional Hot Air Tool SWT-NS3400A Operation Guide

Geo Hot Wedge Welder SWT NS800 Operation Guide

Compact HDPE Hot Wedge Welding Machine SWT-NSGM1 Operation Guide

Related News

SUBSCRIBE NEWSLETTER

Dear customer, thank you for your attention! We provide high-quality machinery and equipment and look forward to your orders. Please inform us of your needs and we will respond quickly!