-

Email:info@peweldingmachine.com

Email:info@peweldingmachine.com

-

+86-137 3974 5191

+86-137 3974 5191

-

Add:

Add:NO.355,Youyi Street,Qiaoxi District,Shijiazhuang,Hebei,China.

Hot Air Welder for Vinyl & Plastic Sinclair & Nitrogen Options Available

heinä . 06, 2025 12:08

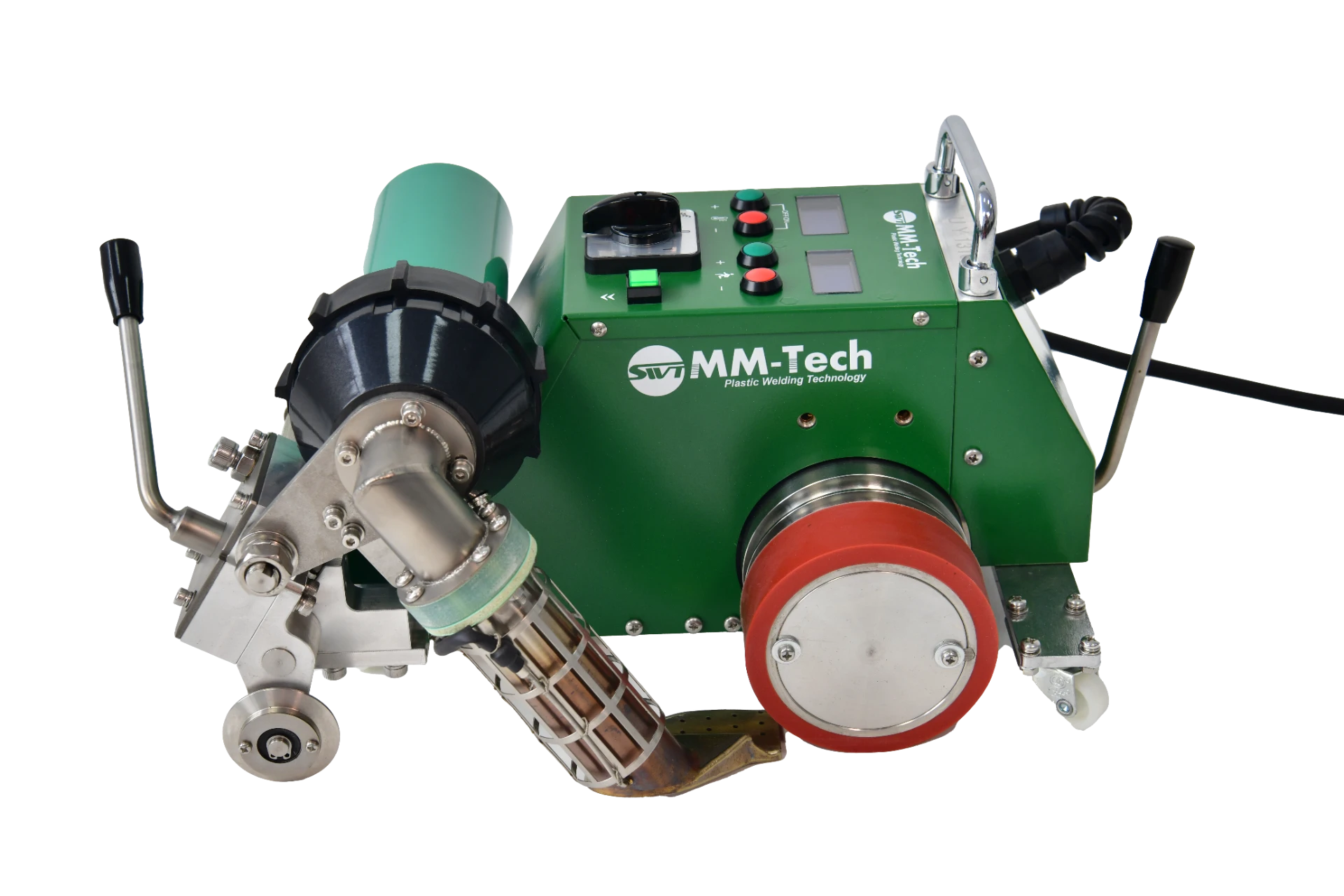

Ever ruined a job with weak vinyl seams? Or lost hours to plastic parts failing under stress? You’re not alone. In 2023, the global demand for high-quality hot air welder

equipment jumped by 19%. With over 60% of welders citing durability and speed as their 1 pain points, it’s clear: efficiency isn’t a luxury. It’s a lifeline.

(hot air welder)

Why Hot Air Welders Are Taking Over the Industry

Hot air welders transform your workflow. Traditional bonding can’t match the speed, control, or seamless finish you get here. Picture this: A hot air vinyl welder reaches welding temperatures within 2 minutes. That means less downtime, more completed pieces, and a sharper finish. With a nitrogen hot air plastic welder, you get even better thermal control and oxidation resistance. The result? Welds that last up to 40% longer. Advanced models—like the acclaimed Sinclair hot air welder—offer digital automation and precision airflow. This isn't just about melting plastic; it’s about future-proofing your projects.

The Tech Edge: Comparing Leading Hot Air Welders

Need speed? Sinclair’s Pro leads with digital precision and robust ceramic elements for 24/7 output. Leaning toward green tech? Nitrogen models boost weld quality while slashing oxidation risk. For budget-friendly operations, the classic vinyl welder holds its ground. Which edge fits your business best?

Tailored Hot Air Welding: Your Custom Solution Awaits

Every project is unique. Off-the-shelf doesn’t cut it. That’s why we put customization at your fingertips. Choose your ideal nozzle width, airflow intensity, and automation level. For automotive repairs, opt for a nitrogen hot air plastic welder with micro-adjustments for high-stress plastics. Large-scale vinyl billboards? Ramp up with an extra-wide, high-output hot air vinyl welder. It’s your call. We even offer on-site training, so your team never skips a beat. Why struggle with one-size-fits-all, when you could dominate with solutions engineered for your workflow?

Hot Air Welder in Action: Real-World Wins

Still on the fence? Let’s check the facts: Last year, a Midwest sign company switched to our automated hot air welders. Output jumped by 31%. Downtime? Down 46%. Automotive shops using nitrogen welders slashed defect rates by half. In the plastics industry, a large OEM saw warranty claims drop 64% with Sinclair hot air welders in production. What could optimized welding do for you?

Ready to Transform Your Workflow?

Don’t settle for less. Experience the future of hot air welding. Whether you need high-speed vinyl fusion, ultra-durable plastic bonds, or custom-grade equipment for demanding jobs, we’re ready to partner with you. Contact us today—let’s engineer your perfect welder. Our experts at Sinclair are standing by to boost your business, shrink your defects, and power your brand. Level up with precision. Weld smarter. Weld stronger—today!

(hot air welder)

FAQS on hot air welder

Q: What is a hot air welder used for?

A: A hot air welder is used to join or repair thermoplastic materials by directing hot air at them. It is commonly used in plastic fabrication, roofing, and flooring installations. The heat softens the plastic for bonding or reshaping.Q: How does a hot air vinyl welder differ from other hot air welders?

A: A hot air vinyl welder is specifically designed to work with vinyl materials. It provides precise temperature control to avoid damaging the vinyl. This makes it ideal for flooring, banners, and tarpaulin welding.Q: What features distinguish the Sinclair hot air welder?

A: Sinclair hot air welders are known for their durability, easy-to-use controls, and consistent performance. They often offer adjustable temperature settings and interchangeable nozzles. These features support a variety of plastic welding applications.Q: Why is nitrogen used in a nitrogen hot air plastic welder?

A: Nitrogen is used in hot air plastic welders to prevent oxidation during the welding process. This results in stronger, cleaner welds. It's especially important when welding automotive plastics or other sensitive materials.Q: Can hot air welders be used for repairing automotive plastics?

A: Yes, hot air welders, including nitrogen hot air plastic welders, are commonly used for automotive plastic repairs. They can fix bumpers, headlights, and other components efficiently. Using nitrogen ensures minimal discoloration and a strong bond.Related Products

Related Video

Geo Hot Wedge Welder With Digital Display SWT NS800D Operation Guide

Heavy-Duty Geo Hot Wedge Welder SWT-NS900 Operation Guide

Powerful Professional Hot Air Tool SWT-NS3400A Operation Guide

Geo Hot Wedge Welder SWT NS800 Operation Guide

Compact HDPE Hot Wedge Welding Machine SWT-NSGM1 Operation Guide

Related News

SUBSCRIBE NEWSLETTER

Dear customer, thank you for your attention! We provide high-quality machinery and equipment and look forward to your orders. Please inform us of your needs and we will respond quickly!